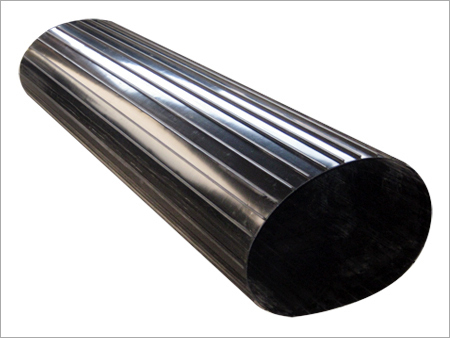

HDPE T-Grip Liner

HDPE T-Grip Liner Specification

- Yield Strength

- 19 MPa

- Tensile Strength

- 23 MPa

- Connection Type

- Extrusion Welded / Butt Welded

- Bend Radius

- As per manufacturers guidelines

- Flexibility

- High Flexibility

- Sealing Type

- Waterproof Seam

- Coating Type

- No additional coating

- Tolerance

- 0.5 mm

- Temperature Range

- -30C to +80C

- Product Type

- HDPE T-Grip Liner

- Material

- High Density Polyethylene (HDPE)

- Connection

- Thermal Welding / Extrusion Welding

- Shape

- T-Grip Profile

- Standard

- ASTM/IS Standard

- Surface Treatment

- Smooth and Textured Surface

- Section Shape

- T-Shaped Profile

- Length

- 2 m to 6 m (customizable)

- Thickness

- 5 mm to 15 mm

- Color

- Black

- Usage

- Corrosion Protection, Chemical Resistance lining

- Rated Pressure

- Not Pressure Rated

- Application

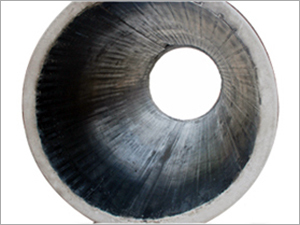

- Concrete protection in tanks, drainage channels, water treatment plants

- Material Grade

- Virgin HDPE

- Density

- 0.94 g/cm to 0.96 g/cm

- Chemical Resistance

- Excellent resistance to acids, alkalis, and salts

- Standards Compliance

- ISO 4427, DIN 16963

- Abrasion Resistance

- High

- Installation

- Hot Air Welding, Extrusion Welding

- Packaging

- Rolls or sheets, as specified

- Profile Height

- 20 mm to 30 mm

- Environmental Suitability

- Suitable for underground and submerged applications

- Water Absorption

- Negligible

- Elongation at Break

- 600%

- Hardness (Shore D)

- 60-65

- UV Resistance

- Good UV stability

- Manufacturing Method

- Extruded profile

- Profile Width

- 150 mm to 500 mm

HDPE T-Grip Liner Trade Information

- Minimum Order Quantity

- 100000 Pieces

- Supply Ability

- 200 Pieces Per Day

- Delivery Time

- 2 Days

About HDPE T-Grip Liner

Key Points:

- Sophisticated appearance

- Excellent finish

- Sturdy design

- Hassle free fitting

Superior Durability for Demanding Environments

The HDPE T-Grip Liner stands out for its engineered resilience, boasting high tensile strength ( 23 MPa), elongation at break ( 600%), and Shore D hardness of 60-65. Its formulation delivers robust protection against mechanical wear, chemical exposure, and moisture ingress, ensuring long-term integrity in both underground and submerged applications.

Simple and Reliable Installation Methods

Installation of this liner is facilitated by hot air welding or extrusion welding techniques, which create durable, waterproof seams. Customizable lengths (2 m to 6 m) and roll or sheet packaging options enhance on-site handling, accommodating diverse project requirements with precision and efficiency.

Versatile Protection for Infrastructure

This T-Grip liner is engineered for a broad spectrum of uses, especially concrete protection in tanks, water treatment plants, and drainage systems. Its high flexibility and reliable connection types ensure secure mounting and longevity, resulting in substantial cost savings by reducing concrete deterioration and maintenance needs.

FAQs of HDPE T-Grip Liner:

Q: How is the HDPE T-Grip Liner installed for optimal waterproofing?

A: The HDPE T-Grip Liner is installed using hot air or extrusion welding, which fuses sections together for seamless, waterproof joints. This thermal bonding technique is essential for maintaining the liners integrity in demanding environments.Q: What benefits does the T-Grip profile provide in concrete protection applications?

A: The T-Grip profile anchors securely into concrete, enhancing mechanical interlock and preventing liner displacement. This feature significantly improves resistance against chemical penetration and prolongs the lifespan of concrete structures exposed to aggressive substances.Q: Where can this liner be used most effectively?

A: This liner excels in water treatment plants, tanks, drainage channels, and other infrastructure requiring protection from corrosion and chemical attack. Its suitability for underground and submerged applications makes it versatile for numerous industrial projects.Q: What type of chemical resistance does the HDPE T-Grip Liner offer?

A: Manufactured from virgin HDPE, the liner exhibits exceptional resistance to acids, alkalis, and salts, making it ideal for environments where chemical exposure is frequent and severe.Q: When should a contractor choose a smooth versus textured surface liner?

A: Smooth surfaces are typically chosen for easy cleaning and reduced friction, while textured surfaces enhance mechanical bonding with concrete. Selection depends on the specific performance and installation requirements.Q: What is the recommended process for connecting liner sections on-site?

A: Sections are joined by thermal welding (either hot air or extrusion welding), which produces strong, watertight seams. The process should be guided by manufacturer recommendations to ensure proper installation and performance.Q: What are the primary benefits of using this liner over alternative materials?

A: The liner provides high flexibility, UV stability, and excellent abrasion and chemical resistance, all while meeting stringent international standards. These properties result in longevity, reduced maintenance, and comprehensive protection for concrete infrastructure.

- Minimum Order Quantity

- 100000 Pieces

- Supply Ability

- 200 Pieces Per Day

- Delivery Time

- 2 Days

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pre Cast Concrete Product Category

Box Culverts

Minimum Order Quantity : 100000 Pieces

Color : Grey

Diameter : N/A (Rectangular Section)

Temperature Range : 10C to 60C

Outer Diameter : N/A (Rectangular Section)

Thickness : 50 mm 300 mm (as per design)

HDPE Lined RCC Pipes

Minimum Order Quantity : 100000 Pieces

Color : Grey with Black Lining

Diameter : 300 mm to 2200 mm

Temperature Range : 10C to +60C

Outer Diameter : 300 mm to 2200 mm

Thickness : 40 mm to 150 mm

Perforated RCC Pipes

Minimum Order Quantity : 100000 Pieces

Color : Natural Grey

Diameter : Varies (commonly 150 mm to 1000 mm)

Temperature Range : 10C to 60C

Outer Diameter : 150 mm to 1000 mm

Thickness : Ranges from 75 mm to 150 mm

Jacking Pipe

Minimum Order Quantity : 100000 Pieces

Color : Grey

Diameter : 1000 mm

Temperature Range : 10C to 60C

Outer Diameter : 1000 mm

Thickness : 150 mm

Send Inquiry

Send Inquiry Send SMS

Send SMS