Jacking Pipe

Jacking Pipe Specification

- Connection Type

- Push-fit (Rubber Gasket)

- Tensile Strength

- 500 kg/cm

- Temperature Range

- -10C to 60C

- Tolerance

- 2 mm

- Sealing Type

- Rubber Ring Sealed

- Yield Strength

- 400 kg/cm

- Flexibility

- Rigid

- Coating Type

- Concrete

- Bend Radius

- Rigid No Bend

- Diameter

- 1000 mm

- Product Type

- Jacking Pipe

- Material

- Reinforced Concrete

- Connection

- Bell and Spigot / Collar Joint

- Shape

- Cylindrical

- Standard

- IS 458 / ASTM C76

- Surface Treatment

- Smooth Concrete Finish

- Outer Diameter

- 1000 mm

- Section Shape

- Round

- Length

- 2500 mm

- Thickness

- 150 mm

- Color

- Grey

- Usage

- Microtunneling, Trenchless Pipe Installation

- Rated Pressure

- Up to 0.6 MPa

- Application

- Water Supply, Sewerage, Stormwater

- Material Grade

- M40 Concrete

- Density

- 2400 kg/m³

- Transportation

- As per client requirement

- Core Testing

- Available upon request

- Fire Resistance

- Non-combustible

- Packaging

- Loose / Bundled

- Load Bearing Capacity

- Up to 40 tonnes

- Jointing System

- Rubber Gasket & Spigot

- Water Absorption

- < 6% by mass

- Internal Diameter

- 800 mm

- External Surface Finish

- Smooth/Plain

- End Finish

- Beveled / Plain

Jacking Pipe Trade Information

- Minimum Order Quantity

- 100000 Pieces

- Supply Ability

- 200 Pieces Per Day

- Delivery Time

- 2 Days

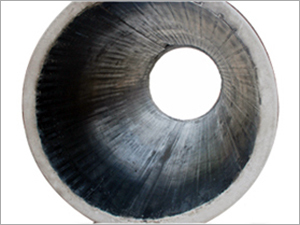

About Jacking Pipe

Key Points:

- Rigidness

- Flawless finish

- Fire resistance

- Long life

Engineered for Maximum Strength and Reliability

Fabricated using M40 grade reinforced concrete, this jacking pipe offers excellent strength with a rated tensile strength of 500 kg/cm and yield strength of 400 kg/cm. Its non-combustible, rigid nature and advanced sealing system ensure dependable performance in infrastructure projects involving significant pressure and load demands.

Adaptable to Diverse Trenchless Applications

Perfect for microtunneling and trenchless installations, this cylindrical pipe boasts a smooth finish both inside and out. Its precise construction (2 mm tolerance), fire resistance, and minimal water absorption (< 6%) make it ideal for water supply, sewerage, and stormwater networks in varied environments.

Customizable Solutions and Client-Focused Service

Supplied by experienced exporters, manufacturers, and traders in India, these pipes come with flexible packaging and transportation options. Core testing is available on request, ensuring strict quality guarantees. Client-specific needs for length, connection type, and finish are accommodated to deliver suited solutions.

FAQs of Jacking Pipe:

Q: How is the jacking pipe installed in trenchless and microtunneling projects?

A: The jacking pipe is installed using a push-fit system featuring a rubber gasket and spigot or collar joint. This allows for efficient and secure pipe connections during microtunneling or trenchless projects, minimizing ground disruption while maintaining alignment and waterproof sealing.Q: What benefits does a reinforced concrete jacking pipe offer for water supply and sewerage applications?

A: Reinforced concrete jacking pipes provide high load-bearing capacity, durability, non-combustibility, and minimal water absorption. These properties make them ideal for transporting water, sewage, and stormwater under demanding conditions, ensuring longevity and reliable service.Q: When should core testing be requested for these pipes?

A: Core testing can be requested whenever verification of pipe strength, density, and material quality is required. It is especially recommended for critical projects or where compliance with specific technical standards must be documented.Q: Where are these jacking pipes typically used?

A: These pipes are used in infrastructure projects such as water supply systems, underground sewerage, and stormwater drainage, particularly where trenchless or microtunneling techniques are employed. They are suitable for both urban and industrial environments.Q: What is the process of ensuring proper joint sealing in these pipes?

A: Proper sealing is achieved using a rubber ring and a bell and spigot or collar joint system. The rubber gasket ensures a leak-proof connection, even under rated pressures up to 0.6 MPa, maintaining system integrity and preventing infiltration or exfiltration.Q: How does the pipes structure support heavy loads up to 40 tonnes?

A: The pipes reinforced concrete construction, along with precise manufacturing (M40 concrete grade and 150 mm thickness), ensures a high load-bearing capacity. This enables the pipe to withstand the rigors of underground installation and the heavy loads imposed by above-ground activity.Q: What advantages does the smooth/concrete finish provide?

A: A smooth concrete finish on the external and internal surfaces reduces friction during installation, aids in easier joint assembly, and supports efficient fluid flow within the pipe. It also helps prevent adhesion of debris and buildup along the pipes interior.

- Minimum Order Quantity

- 100000 Pieces

- Supply Ability

- 200 Pieces Per Day

- Delivery Time

- 2 Days

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pre Cast Concrete Product Category

Box Culverts

Minimum Order Quantity : 100000 Pieces

Surface Treatment : Other, Smooth Finish

Tensile Strength : 300400 kg/cm (Depending on Grade)

Temperature Range : 10C to 60C

Material : Other , Reinforced Concrete

Application : other, Civil Construction, Road Works, Water Conveyance

HDPE Lined RCC Pipes

Minimum Order Quantity : 100000 Pieces

Surface Treatment : Other, HDPE Lined, Smooth Finish

Tensile Strength : Min. 25 MPa (HDPE Liner)

Temperature Range : 10C to +60C

Material : HDPE

Application : other, Municipal, Industrial, Irrigation

Perforated RCC Pipes

Minimum Order Quantity : 100000 Pieces

Surface Treatment : Other, Smooth/Uncoated

Tensile Strength : Approx. 3.5 MPa

Temperature Range : 10C to 60C

Material : Other , Reinforced Cement Concrete (RCC)

Application : other, Drainage of excess water, water management

U-Shaped Plastic Cable Tray

Minimum Order Quantity : 100000 Pieces

Surface Treatment : Other, Smooth Finish

Tensile Strength : 400 kg/cm

Temperature Range : 20C to 65C

Material : Plastic

Application : other, Electrical Wiring Support

Send Inquiry

Send Inquiry Send SMS

Send SMS